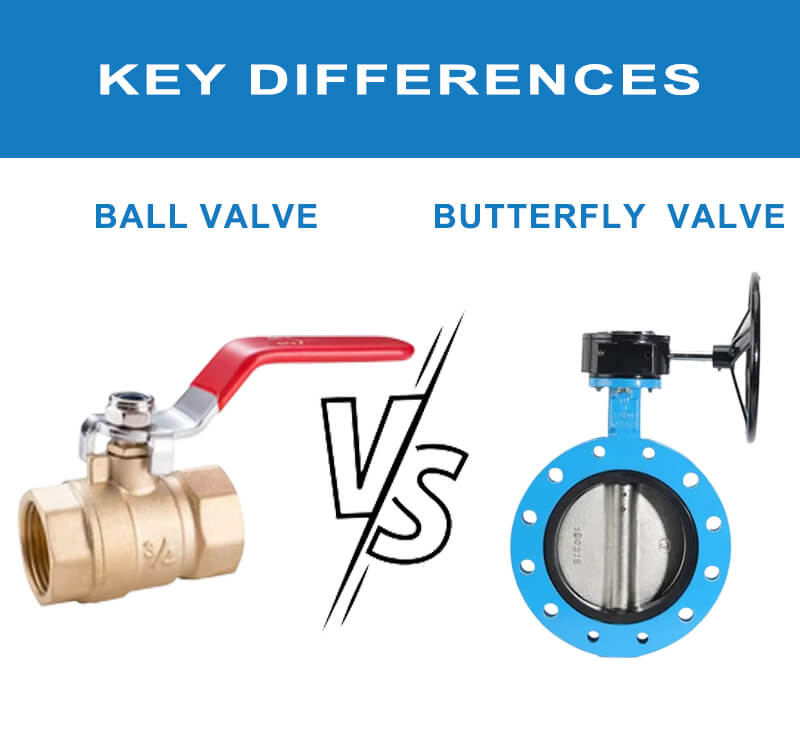

When choosing between butterfly valves and ball valves for specific applications, understanding their differences is crucial. Both are highly effective in controlling fluid flow, but their designs and functionalities make them suitable for distinct purposes. Let’s explore why a butterfly valve may be a better choice in certain situations, especially in industries like marine, HVAC, water treatment, and more.

1. Compact Design and Space Efficiency

Butterfly valves are compact and lightweight compared to ball valves. This design offers several advantages.

Space-saving installation: Ideal for tight spaces on ships or in industrial systems.

Lower weight: Reduces stress on pipelines, making them suitable for large-scale piping networks.

In contrast, ball valves are bulkier and may require more room for installation and operation, particularly in larger sizes.

2. Cost-Effectiveness for Larger Systems

When dealing with large-diameter pipelines, butterfly valves are often more economical.

Lower material costs: Butterfly valves require less material due to their smaller disc design compared to the solid ball of a ball valve.

Ease of manufacturing: Simplified construction makes them less expensive to produce.

This cost efficiency makes butterfly valves a preferred choice for applications like ballast water systems, cooling systems, and other large-scale installations.

3. Effective for Throttling Applications

Butterfly valves are well-suited for throttling and flow regulation:

Precise control: The disc’s rotation allows incremental flow adjustments.

Minimal pressure drop: Optimized for maintaining flow dynamics in partially open positions.

Ball valves, while effective for on/off control, are less precise in throttling applications due to their design.

4. Durability in Corrosive and Marine Environments

Butterfly valves, especially those made from materials like stainless steel, bronze, or with epoxy coatings, offer high corrosion resistance.Commonly used in marine environments to handle seawater, chemicals, and other corrosive fluids.Require less frequent maintenance, reducing operational downtime compared to ball valves in similar conditions.

5. Simpler Operation and Maintenance

Butterfly valves are easier to operate and maintain due to their design

Quarter-turn operation: A simple 90-degree turn opens or closes the valve, making automation easier.

Fewer moving parts: Reduces the likelihood of mechanical failure, which can be more complex in ball valves.

Their simple design ensures reliable performance with minimal maintenance requirements.

6. Applications Requiring Large Flow Capacities

Butterfly valves excel in handling large flow volumes due to their streamlined design.Suitable for systems requiring high flow rates, such as cooling water circulation on ships.Provide bidirectional flow control, ensuring flexibility in various operational scenarios.Ball valves, with their smaller bore, may restrict flow in larger systems.

Post time: Jan-18-2025