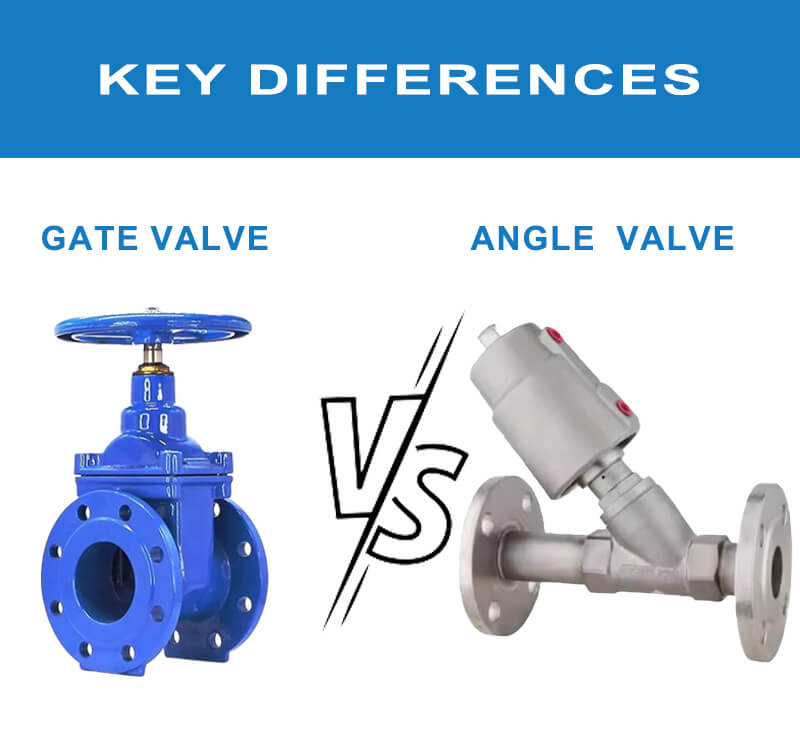

When managing fluid flow in industrial and marine systems, gate valves and angle valves are among the most commonly used. Both serve critical roles but differ in design, functionality, and applications. This comprehensive comparison will help you decide which valve is the best fit for your specific needs.

1. Structural Differences

Gate Valve:Gate valves operate with a linear motion mechanism where a wedge-shaped gate moves vertically to control flow.They feature a straight-through design, ensuring minimal turbulence and pressure loss.The valve body is compact, with a rising or non-rising stem option depending on the space available.

Angle Valve:Angle valves have a 90-degree design that redirects the flow, combining control and direction change in one component.This design reduces the number of fittings needed in piping systems.It is better suited for applications where space constraints and sediment buildup are concerns.

2. Functional Differences

Gate Valve:Primarily designed for on/off control rather than flow regulation.Its full-bore opening allows for unobstructed flow, making it ideal for high-volume systems.Partial opening can cause gate damage due to cavitation or vibration.

Angle Valve:Engineered for flow regulation and directional control.The 90-degree design allows for precise pressure adjustments, commonly required in cooling circuits or boiler systems.Its ability to handle sediment makes it effective in systems with debris-laden fluids.

3. Performance in Marine Systems

Gate Valve in Marine Systems:Gate valves are extensively used in main pipelines, ballast water systems, and bilge systems due to their:High-pressure handling capability.Full-bore design, which minimizes flow resistance and maximizes efficiency.Durability in isolating flow in critical operations.

Angle Valve in Marine Systems:Angle valves excel in auxiliary systems such as cooling water and chemical dosing lines.Their compact size suits confined spaces on ships.They provide better control over flow direction and pressure regulation, enhancing system performance.

4. Material Considerations

Both valve types are available in marine-grade materials like bronze, brass, stainless steel, and cast iron, depending on the application.

Gate valves often require corrosion-resistant alloys for high-pressure seawater applications.

Angle valves, due to their exposure to sediment or high-temperature fluids, benefit from anti-corrosive coatings and reinforced sealing mechanisms.

6. Choosing the Right Valve

Choose Gate Valves for:Applications requiring full flow or complete shutoff.Large pipelines where minimizing pressure loss is critical.Systems handling clean fluids, such as freshwater or fuel.

Choose Angle Valves for:Throttling applications that require precise flow adjustments.Locations where a 90-degree turn simplifies piping layouts.Handling debris-laden fluids or systems prone to sedimentation.

7. Applications in Various Industries

Marine Applications:Gate valves are favored for main seawater lines, while angle valves excel in cooling systems and auxiliary circuits.

Industrial Applications:Gate valves are used in oil pipelines, and angle valves find use in chemical processing.

Post time: Jan-16-2025