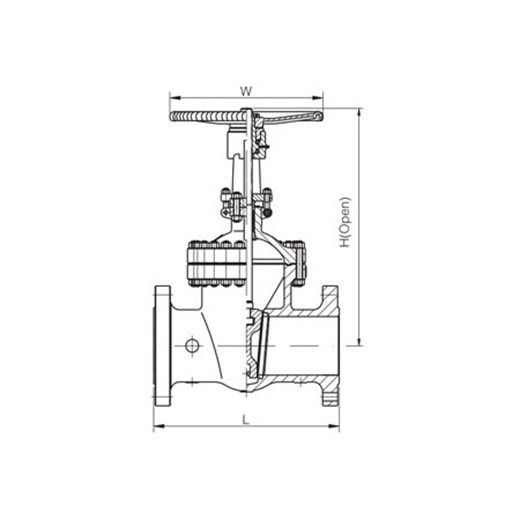

API600 Class 2500 OS&Y Cast Steel Gate Valve

GAV701-2500

Features

Product Overview

API600 Class 2500 OS&Y Cast Steel Gate ValveDesigned for use in high temperature steam and water, this multipurpose gate valve can be used in a wide variety of general purpose applications including vents, drains and isolation of compressors, condensers, heaters, pumps, water lines, heat exchangers, bypass lines, flash tanks, control valves, etc.

Technical Requirement

· Design and Manufacture Conform to API 600

· Flange dimensions Conform to ASME B16.5

· Face to Face dimensions Conform to ASME B16.10

· Testing Conform to API 598

· Driving mode: hand wheel, bevel gear, electric

Dimensions Data

Specification

| NO. | PART | ASTM Material | ||||

| WCB | LCB | WC6 | CF8(M) | CF3(M) | ||

| 1 | BODY | A216 WCB | A352 LCB | A217 WC6 | A351 CF8(M) | A351 CF3(M) |

| 2 | GATE | A216 WCB+13Cr | A352 LCB+13Cr | A217 WC6+STL | A351 CF8(M) | A351 CF3(M) |

| 3 | SEAT | A105+13Cr | A105+13Cr | A217 WC6+STL | A351 CF8(M)+STL6 | A351 CF3(M)+STL6 |

| 4 | STEM | A182 F6 | A182 F6 | A182 F6 | A182 F304/F316 | A182 F304L/F316L |

| 5 | BONNET BOLT | A193 B7 | A320 L7 | A193 B16 | A193 B8(M) | A193 B8(M) |

| 6 | BONNET NUT | A194 2H | A194 7 | A194 4 | A194 8(M) | A194 8(M) |

| 7 | GASKET | SS304+GRAPHITE | PTFE/SS304+GRAPHITE | PTFE/SS316+GRAPHITE | ||

| 8 | BONNET | A216 WCB | A352 LCB | A217 WC6 | A351 CF8(M) | A351 CF3(M) |

| 9 | BACKSEAT | A182 F6 | A182 F6 | A182 F6 | - | - |

| 10 | PACKING | FLEXIBLE GRAPHITE | PTFE/FLEXIBLE GRAPHITE | |||

| 11 | GLAND | A182 F6 | A182 F6 | A182 F6 | A182 F304 | A182 F304L/F316L |

| 12 | GLAND FLANGE | A216 WCB | A352 LCB | A217 WC6 | A351 CF8(M) | A351 CF3(M) |

| 13 | GLAND EYEBOLT | A193 B7 | A193 B8 | A193 B8 | ||

| 14 | NUT | A194 2H | A194 8 | A194 8 | ||

| 15 | PIN | AISI 1025 | AISI 1025 | |||

| 16 | STEM NUT | BRONZE | BRONZE | |||

| 17 | HANDWHEEL NUT | AISI 1035 | AISI 1035 | |||

| 18 | SCREW | ASTM A36 | ASTM A36 | |||

| 19 | HANDWHEEL | A536 60-40-18 | A536 60-40-18 | |||

| 20 | BEARING GLAND | AISI 1035 | AISI 1035 | |||

| 21 | GREASE NIPPLE | BRASS | BRASS | |||

| 22 | NAMEPLATE | SS304 | SS304 | |||

Dimensions data(mm)

| Size | in | 2 | 21/2 | 3 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 |

| mm | 50 | 65 | 80 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | |

| L/L1 (RF/BW) |

in | 17.75 | 20 | 22.75 | 26.5 | 36 | 40.25 | 50 | 56 | - | - | - | - | - |

| mm | 451 | 508 | 578 | 673 | 914 | 1022 | 1270 | 1422 | - | - | - | - | - | |

| L2 (RTJ) |

in | 17.88 | 20.5 | 23 | 26.88 | 36.5 | 10.88 | 50.88 | 56.88 | - | - | - | - | - |

| mm | 454 | 514 | 584 | 683 | 927 | 1038 | 1292 | 1445 | - | - | - | - | - | |

| H (OPEN) |

in | 21.88 | 29 | 35 | 41.5 | 57 | 63.38 | 81.75 | 89.75 | - | - | - | - | - |

| mm | 631 | 736 | 890 | 1055 | 1450 | 1610 | 2075 | 2280 | - | - | - | - | - | |

| D0 | in | 12 | 18 | 20 | 20 | 24 | 24 | 24 | 24 | - | - | - | - | - |

| mm | 300 | 450 | 500 | 500 | 600 | 600 | 600 | 600 | - | - | - | - | - | |

| WT (Kg) |

RF/RTJ | 155 | 210 | 310 | 580 | 1600 | 2450 | 4570 | 7150 | - | - | - | - | - |

| BW | 124 | 160 | 245 | 460 | 1310 | 2010 | 3800 | 6000 | - | - | - | - | - |

Write your message here and send it to us