Angle Type Storm valve

Product Description

IFLOW vertical storm valve, a reliable and robust solution designed to effectively control and manage stormwater runoff in a variety of industrial and commercial environments. Designed with precision and efficiency in mind, this valve offers a range of features that make it the best choice for your stormwater management needs.

First and foremost, the valve’s vertical design allows for seamless installation and saves space. Its compact footprint makes it ideal for locations with limited space while providing optimal functionality for controlling stormwater flow. Additionally, the valve’s durable construction ensures long-lasting performance, even in harsh industrial environments. Additionally, our vertical storm valves have precise control capabilities to precisely regulate stormwater drainage. This level of control is critical to preventing flooding and managing water flow during heavy rainfall.

The valve operates reliably and requires low maintenance, making it a cost-effective and practical solution for stormwater management systems. Focused on efficiency, durability and precise control, our vertical storm valves provide an exceptional balance of performance and reliability. Trust this valve to effectively manage stormwater runoff, providing peace of mind and protection for your industrial or commercial facility. Choose our vertical stormwater valves for a reliable and high-performance solution for your stormwater management needs.

Specification

| Part No. | Material | ||||||

| 1 - Body | Cast Steel | ||||||

| 2 - Bonnet | Cast Steel | ||||||

| 3 - Seat | NBR | ||||||

| 4 - Disc | Stainless Steel, Bronze | ||||||

| 5 - Stem | Stainless Steel, Brass | ||||||

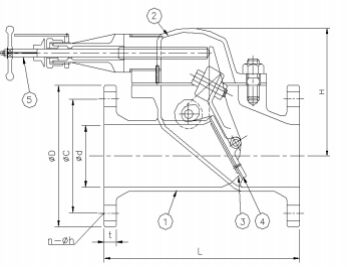

Product wireframe

Storm valve is a flap type non-return valve which is used to discharge the sewage overboard. It is connected to the soil pipe at one end and other end is at ships side so that sewage gets overboard. So it can be overhauled only during drydocks .

Inside the valve flap is there which is attached to a counter weight, and a locking block. The locking block is the piece of the valve that is controlled and operated by the external hand wheel or actuator. The purpose of the locking block is to hold the flap in place which ultimately prevents the flow of fluid.

Dimensions Data

| SIZE | d | FLANGE 5K | FLANGE 10K | L1 | H1 | ||||||

| C | D | n-h | t | C | D | n-h | t | ||||

| 050 | 50 | 105 | 130 | 4-15 | 14 | 120 | 155 | 4-19 | 16 | 170 | 130 |

| 065 | 65 | 130 | 155 | 4-15 | 14 | 140 | 175 | 4-19 | 18 | 200 | 140 |

| 080 | 80 | 145 | 180 | 4-19 | 14 | 150 | 185 | 8-19 | 18 | 220 | 154 |

| 100 | 100 | 165 | 200 | 8-19 | 16 | 175 | 210 | 8-19 | 18 | 250 | 170 |

| 125 | 125 | 200 | 235 | 8-19 | 16 | 210 | 250 | 8-23 | 20 | 270 | 198 |

| 150 | 150 | 230 | 265 | 8-19 | 18 | 240 | 280 | 8-23 | 22 | 310 | 211 |

| 200 | 200 | 280 | 320 | 8-23 | 20 | 290 | 330 | 12-23 | 22 | 400 | 265 |